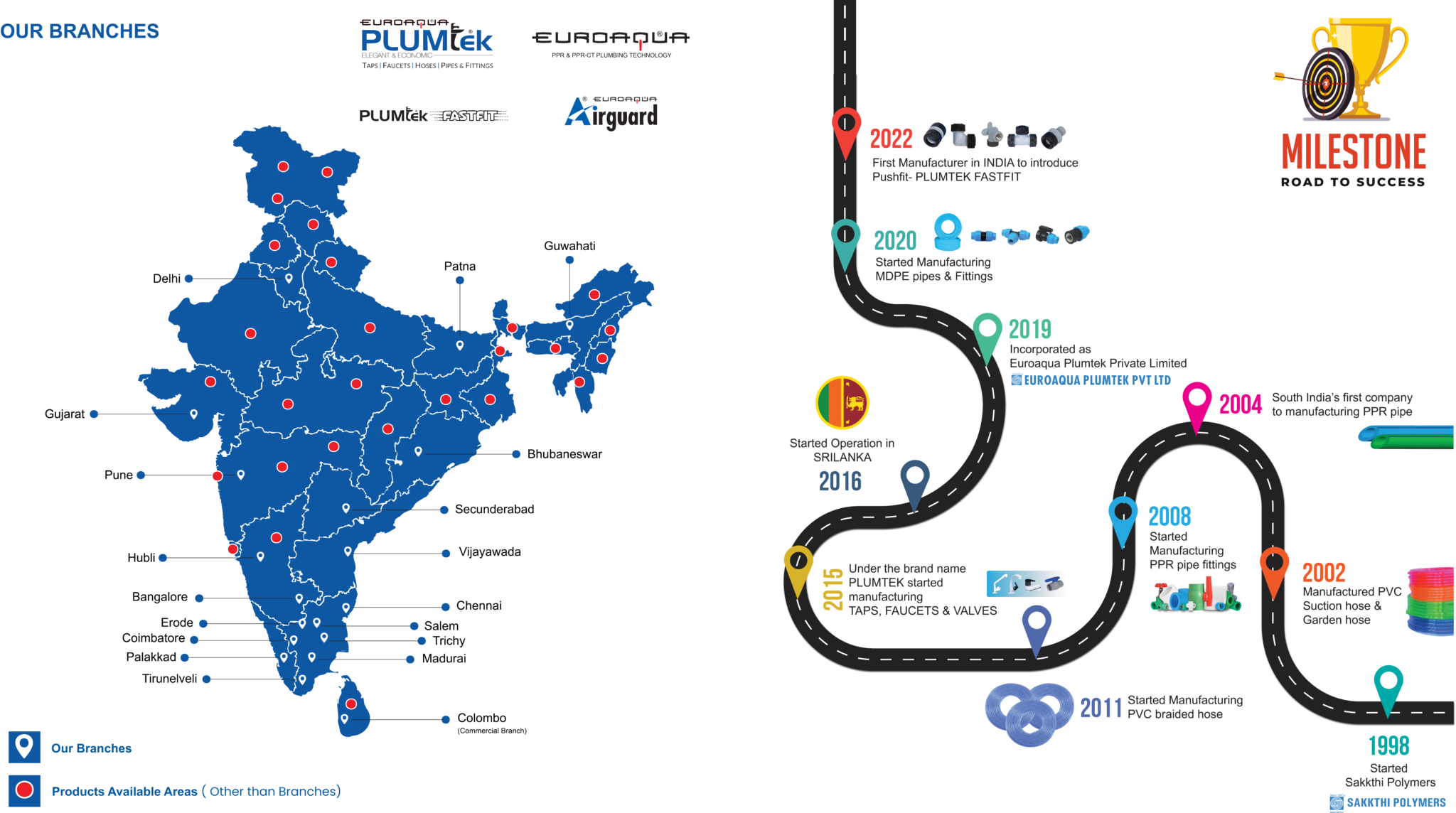

Euroaqua Plumtek private limited is an ISO 9001 2015 certified organization, which was started during the year 1997 by Er. P. Mohan MD & CEO. Our headquarters located at Sankari, Salem, Tamil Nadu and have multiple branches across India & Srilanka. We are specialized in manufacturing PPR, PP-RCT, PPR- FRP, PE-RT, MDPE pipes & fittings. Under the brand name "PLUMTEK", which includes ABS Taps, Faucets, Valves, Hoses and complete solution for Domestic & Industrial plumbing system. We are one of the leading manufacturer and exporter of complete range of PPR pipes and fittings in India and first in South Asia, Introduced PP-RCT technology. We are exporting to more than 15 countries across the globe.

1. PPR PIPES & FITTINGS

2. PERT PIPES & FITTINGS

3. TAPS & FAUCETS

4. MDPE PIPES & FITTINGS

5. PVC HOSES.

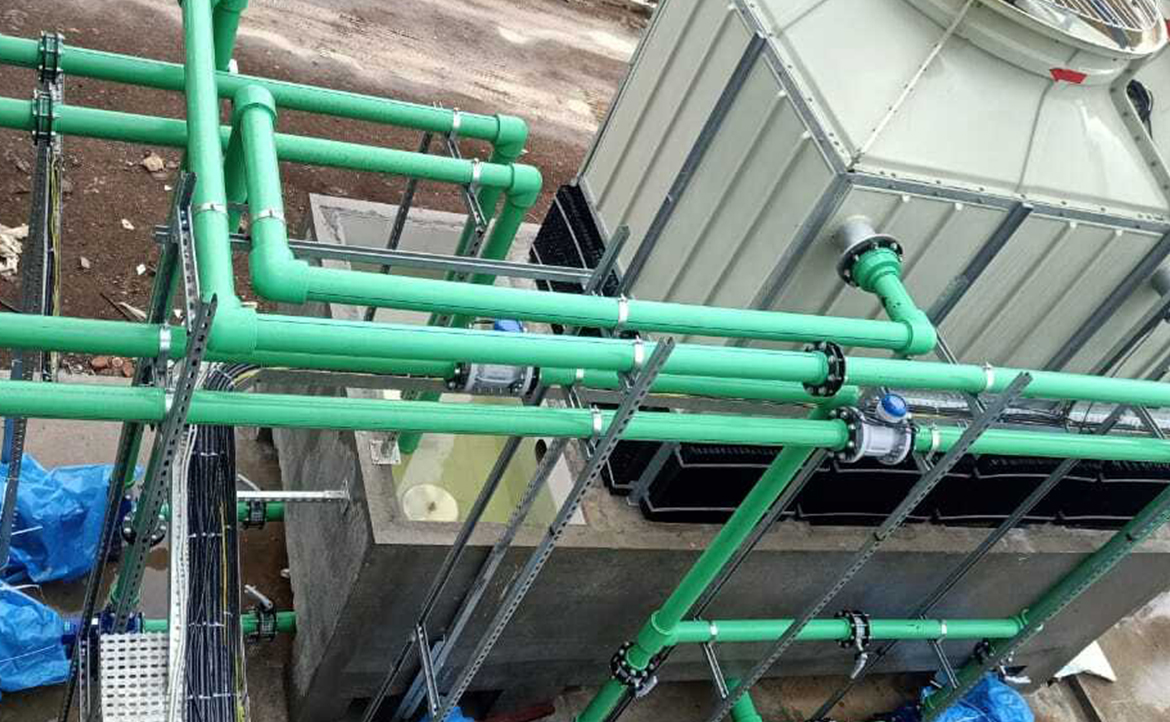

EuroaquaPlumtek PPR pipes and fittings offer advantages such as

high temperature resistance, corrosion resistance, longevity, smooth inner

surface preventing scaling and buildup, ease of installation, and compliance

with international standards.

Yes, EuroaquaPlumtek PPR pipes and fittings are suitable for both hot

and cold water applications due to their high temperature resistance.

Yes, Our PPR Pipes & Fittings Certified Food-Grade for Ultimate Safety

and Quality Assurance.

EuroaquaPlumtek PPR pipes and fittings are resistant to a wide range

of chemicals, making them suitable for various chemical applications.

However, compatibility with specific chemicals should be verified before

use.

EuroaquaPlumtek PPR pipes and fittings are typically installed using

heat fusion welding or socket fusion techniques, ensuring strong and

leak-proof joints.

1. Hot & chilled water

2. Infrastructure

3. Air

4. Pharma

5. Food

6. Paper

7. Strong chemicals

8. Leather

9. Textile

10. Solar heat system

11. Hotel industry.